性能特點

◆ 采用高強度機身構造,變形量小,精度高。

◆ 采用OMPI氣動干式離合剎車器。

◆ 滑塊采用兩角六面導路,滑塊導軌采用“高頻淬火”十 “導軌研磨工藝”:磨損小,精度高,精度保持時間長、提高模具使用壽命。

◆ 曲軸采用高強度合金材質42CrMo,強度比45鋼提高了1.3倍,使用壽命更長。

◆ 銅套采用錫磷青銅ZQSn10-1,強度比普通BC6黃銅提高了1.5倍。

◆ 采用高靈敏液壓過載保護裝置,可有效保護沖床和模具使用壽命。

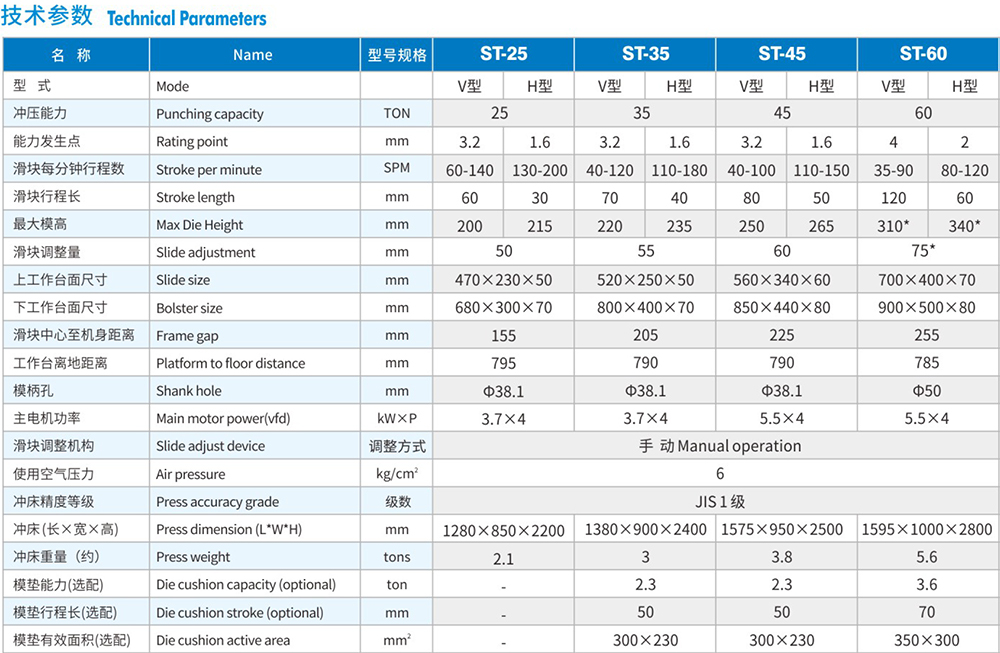

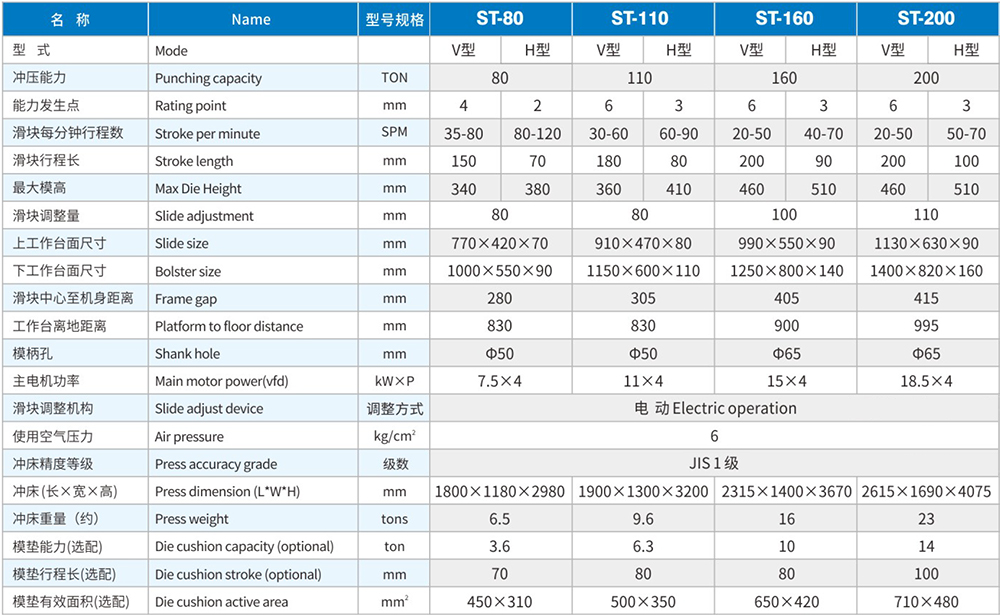

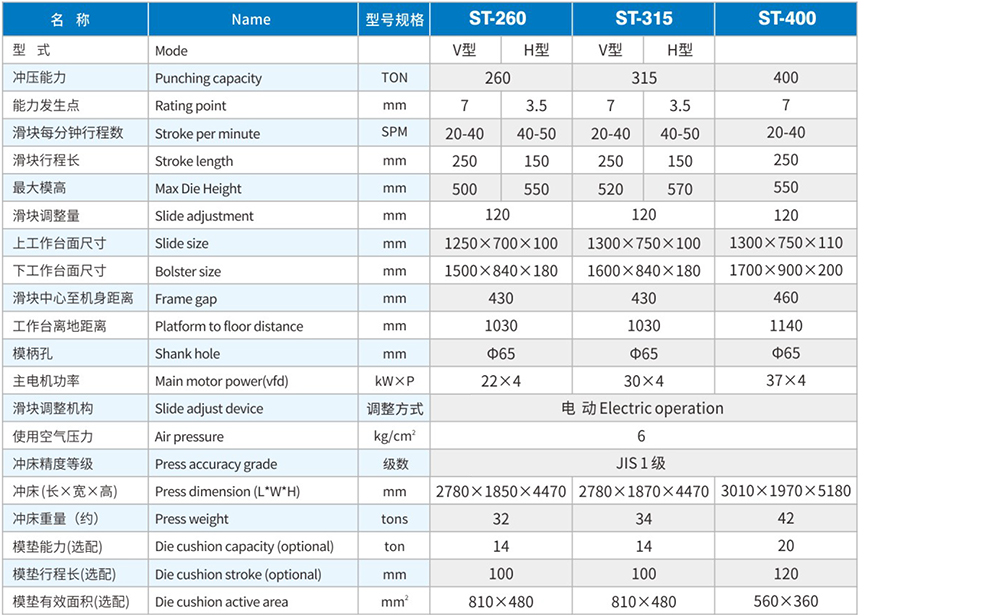

◆ 可選配模墊(氣墊)。

◆ Adopting high-strength body structure, with small deformation and high accuracy.

◆ Adopting OMPI pneumatic dry clutch brake.

◆ The slider adopts a hexagonal guide path with two corners, and the slider guide adopts a "high-frequency quenching" and "rail grinding process": low wear, high accuracy, long accuracy retention time, and improved mold service life.

◆ The crankshaft is made of high-strength alloy material 42CrMo, which is 1.3 times stronger than 45 steel and has a longer service life.

◆ The copper sleeve adopts tin phosphorus bronze ZQSn10-1, which has a strength 1.5 times higher than ordinary BC6 brass.

◆ Adopting a highly sensitive hydraulic overload protection device can effectively protect the service life of the punching machine and mold.

◆ Optional mold pad (air cushion).

下一條:ST開式單點深喉精密沖床